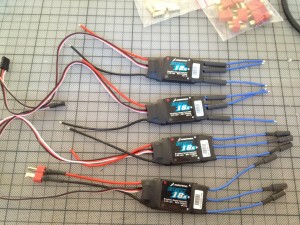

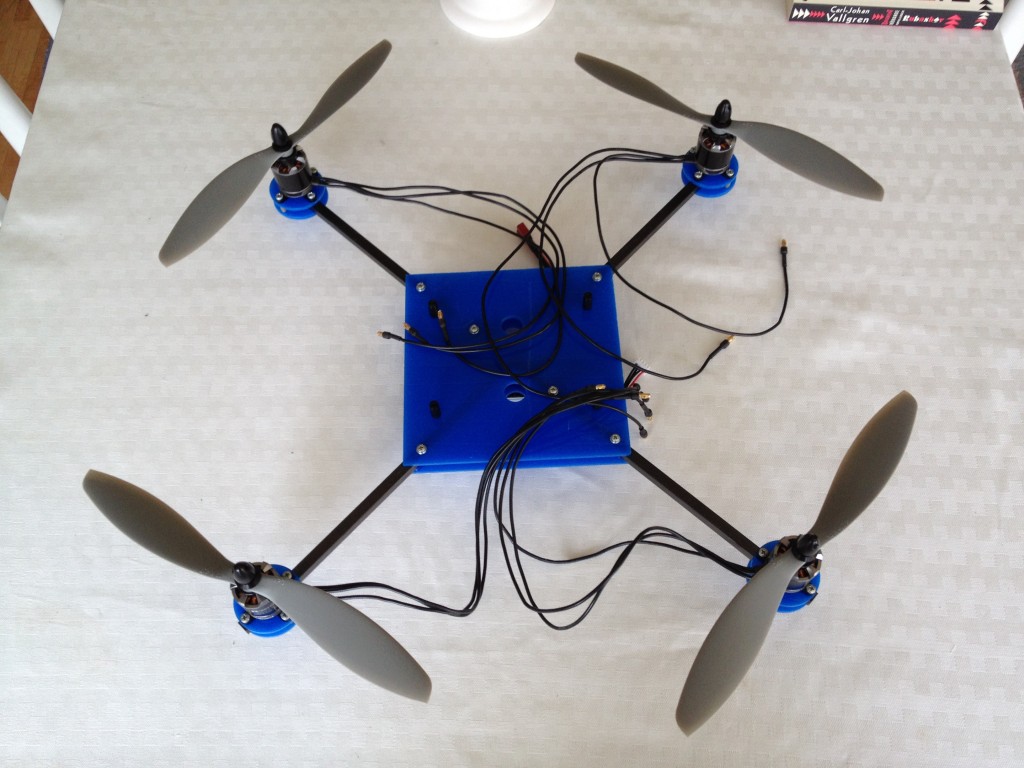

Finally I’ve got some time to continue my work on the copter. I’ve assembled the power distribution cords and hooked it up to an external power supply. Unfortunately my power supply can only give two amps, so there’s some voltage drop outs, but it doesn’t matter for this test. Actually, it means that the voltage regulators on the controller board works great as well.

In this little video you can hear how the engines are changing their speed as the copter is tilted. Sorry for the horrible noise.

[youtube=http://www.youtube.com/watch?v=lcaZebTyx6k&rel=0]